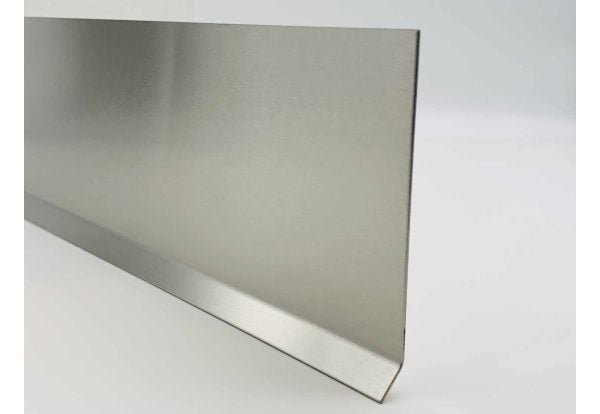

Stainless Steel Wall Base

Configure Your Wall Base

- Automatic Quantity Discounts

- Fast Turnaround!

- Standard and Custom Finishes

- Standard and Custom Sizes

Looking for Wall Base Corners and Joiners?

Personalize your kitchen.

- Fast Turnaround!

Which Thickness of Wall Base Should I Get?

| Q: | 20 ga - Light Duty? |

| A: |

The 20ga wall base is suited for applications where you're less concerned about hitting and more concerned with having a good looking and easy-to-clean solution for your location. It is recommend for areas with light foot traffic and little cart traffic. |

| Q: | 18ga - Medium Duty (Most Popular)? |

| A: |

The 18ga wall bas provides good protection and will stand up to more abuse than the 20ga. The 18ga option is good for general applications such as schools, hospitals, restaurants, office buildings, etc. heavy foot traffic is no issue, and cart traffic in these areas is generally not a problem. |

| Q: | 16ga - Heavy Duty? |

| A: |

The 16ga wall base is good for any application where carts, etc are going to be running in to the wall base on a consistent basis, and you want to ensure your wall won't be destroyed. This is great for warehouses, industrial and commercial facilities, etc. |

Which Stainless Wall Base Finish is The Best?

| Q: | #4 Brushed Finish (Most Popular)? |

| A: |

The #4 brushed finish wall base is the most common and probably what you have already seen in previous applications. The #4 finish is universal, meaning it will match so closely you probably won't notice a difference with #4 brushed finishes from other manufacturers. It is an attractive option, and is a no-brainer when considering stainless steel for a wall base. |

| Q: | Random Swirl Finish? |

| A: |

The wall base with a random swirl finish is excellent for any application where you want a finish that is not only good looking and unique, but specifically made to hide scratches from cleaning. The swirl finish will also help to hide dents that may result from general wear and tear. The random swirl finish matches well with almost any other millwork, decorations, trims, or other finish options you may have, and is a fantastic solution for tough, good looking wall base. |

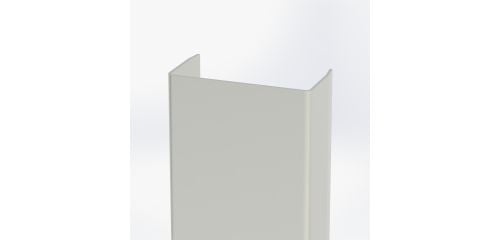

What Are The Wall Base Corner and Joint Options?

| Q: | Inside and Outside Corners? |

| A: |

Instead of going with a traditional corner that may not be installed correctly, we have a solution that is guaranteed to provide an attractive corner every time. Just whip out the grinder or cut-off saw and cut your wall base to length. Don't worry about burned edges, burrs, or other unsightly blemishes at the cut area. Install the wall base and when you're finished, come back and install the corners in minutes. You want to save time and money, annnnnd have a good looking installation? Well, this is your solution. |

| Q: | Joints or Dividers? |

| A: |

Same goes with the dividers, joints, or whatever you call them. Leave a 1/8in - 1/4in gap between each piece of wall base, and don't worry about burrs or burned edges, or if the cut isn't exactly straight. When you're finished, simply come back and slap on the joint covers. These are stuck on with VHB tape, and the only way you're getting them off is with a crowbar. |

Stainless Steel Surface Finishes Explained Clearly!

| Q: | What is the #4 Brushed Finish? |

| A: |

The #4 brushed finish is the most popular available today, and typically utilizes . There are various names for it including brushed, polished, satin, and sometimes even nickel finish. It's the de facto industry standard in commercial, industrial and residential applications where aesthetics and longevity are important. It's also the most consistent across batches and is easier to match when upgrading or adding to previous installations. The #4 brushed finish will never fade and is basically ageless, providing you keep it maintained. |

| Q: | What is the 2B Finish? |

| A: |

The 2B Finish is gray in color and somewhat reflective. It looks good initially, but is extremely difficult to keep pristine in applications where it will be handled and/or cleaned frequently. This has no effect on the performance or longevity of the product, but rather the aesthetics. Fingerprints, oils, and various liquids tend to stain the surface of the metal, resulting in uneven coloring and patches with different shades of gray. In addition, the 2B finish is done at the steel mill and may vary in color from batch to batch. |

| Q: | What is the BA Finish? |

| A: |

BA finish, or Bright Annealed finish is similar to a #8 mirror finish or a chrome finish. While quite uniform, the finish is done at the steel mill and may vary slightly from batch to batch of material. You'll find the BA finish on the inside of dishwashers, laundry machines, refrigerators, etc. The bright annealed finish is achieved by heating up and cooling (annealing) in a controlled environment. |

| Q: | Are Stainless Steel Surfaces Anti-Bacterial? |

| A: |

There is a common misconception about stainless steel being anti-bacterial, like copper, brass and bronze, but that is not the case. However, stainless steel is generally cost effective enough and durable enough to be cleaned and/or sterilized frequently without breaking down the surface or material. This is the reason for its popularity in everything from surgical instruments to restaurants. If it isn't destroyed by carelessness, including denting, abrading, drilling holes, etc, stainless steel will provide one of the longest-lasting and best looking finish options available. |