Stainless Steel Backsplash Tiles

Design Your Tiles

Click Here for Kitchen Visualizer

Click Here for Customer Kitchens

- Sizes Up to 12" x 12"

- Ships in 5-7 Business Days

- FREE Shipping

Need Kitchen Backsplash Samples?

Choose finishes and get your samples in 2 business days.

Shop for Samples- Free 2-Day shipping

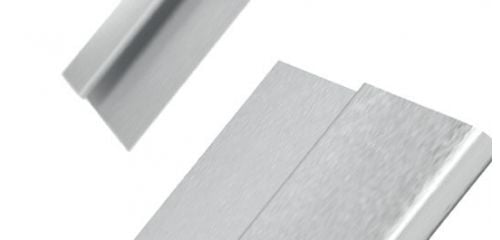

Thickness, Finishes, and Sizing

Material Thickness - 22ga. (.031")

For the material thickness, the stuff the tiles are made with, we offer just the 22 gauge thickness because it provides a good balance between rigidity and weight. It's easier to work with, and plenty heavy enough for any application. The material is about as thick as your credit card. The 22 gauge option is the right thickness for tiles and is heavier than other available stainless steel tiles on the market. We do not apply any backer material so you have an air gap behind them. This is useful for insulation and cuts down on weight.

Tile Thickness - 1/4" and Up:

The minimum thickness for the tiles is 1/4" and this dimension is the overall thickness. Theoretically there is no maximum, but for now we're limiting it to 5/8" due to mounting constraints. Before going thicker, we'd like to test the installation system. We like to know something works up to our standards before offering it, and this is no exception.

Finishes:

The tiles are currently offered in the #4 finish, 2B finish, and embossed finishes. You can create a checkerboard pattern, or mix and match to your heart's content. We do not offer custom colored finishes beyond what you see here.....yet. It's on the horizon, but there are some bugs to iron out before that can happen.

How Are the Tiles Installed?

JTC Metals stainless steel tile is adhered to the wall similar to how ceramic tile is installed. The edges next to the face are rounded, and the consistent finish from the face to the sides provides flexibility to get creative with the installation. For instance, the tiles can be installed without a gap for a unique look that also eliminates the need for grout.

Coming Soon: Proprietary Installation System

We know the pain of finding someone to install tile, and it's not fun. That's why we are working on an installation system that will be so easy to work with, almost anyone can have a gorgeous tile backsplash without the hassle of finding a competent professional.

Stainless Steel Surface Finishes Explained Clearly!

| Q: | What is the #4 Brushed Finish? |

| A: |

The #4 brushed finish is the most popular available today, and typically utilizes . There are various names for it including brushed, polished, satin, and sometimes even nickel finish. It's the de facto industry standard in commercial, industrial and residential applications where aesthetics and longevity are important. It's also the most consistent across batches and is easier to match when upgrading or adding to previous installations. The #4 brushed finish will never fade and is basically ageless, providing you keep it maintained. |

| Q: | What is the 2B Finish? |

| A: |

The 2B Finish is gray in color and somewhat reflective. It looks good initially, but is extremely difficult to keep pristine in applications where it will be handled and/or cleaned frequently. This has no effect on the performance or longevity of the product, but rather the aesthetics. Fingerprints, oils, and various liquids tend to stain the surface of the metal, resulting in uneven coloring and patches with different shades of gray. In addition, the 2B finish is done at the steel mill and may vary in color from batch to batch. |

| Q: | What is the BA Finish? |

| A: |

BA finish, or Bright Annealed finish is similar to a #8 mirror finish or a chrome finish. While quite uniform, the finish is done at the steel mill and may vary slightly from batch to batch of material. You'll find the BA finish on the inside of dishwashers, laundry machines, refrigerators, etc. The bright annealed finish is achieved by heating up and cooling (annealing) in a controlled environment. |

| Q: | Are Stainless Steel Surfaces Anti-Bacterial? |

| A: |

There is a common misconception about stainless steel being anti-bacterial, like copper, brass and bronze, but that is not the case. However, stainless steel is generally cost effective enough and durable enough to be cleaned and/or sterilized frequently without breaking down the surface or material. This is the reason for its popularity in everything from surgical instruments to restaurants. If it isn't destroyed by carelessness, including denting, abrading, drilling holes, etc, stainless steel will provide one of the longest-lasting and best looking finish options available. |